Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Select The Most Appropriate NTC Thermistors

While designing electrical components, its mandatory that they have the required properties to resist sudden temperature changes, which otherwise can lead to numerous hazards. All the electronic products that we use in our day-to-day life from smart watches, phones to laptop all rely on temperature dependent components. NTC thermistors or Negative Temperature Coefficient Thermistors in an electronic product assist in managing the temperature and keeping the product safe and long lasting. Selecting the right type of NTC thermistors within the prescribed thermistor temperature range can be quite a bit of task. Many factors like size, type, material made of, mount used, performance, accuracy etc also come in picture.

Types Of Thermistors

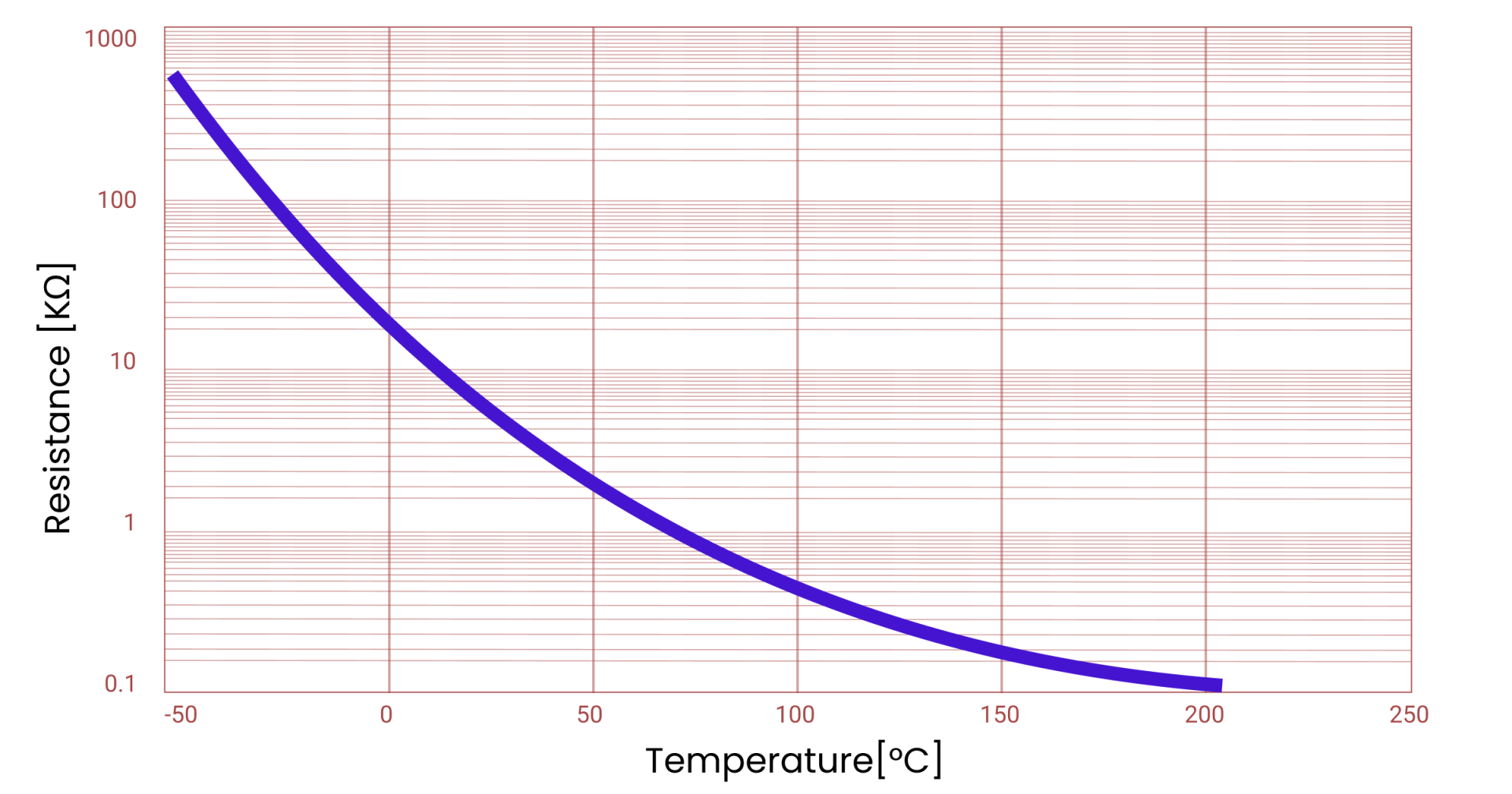

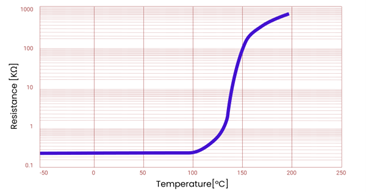

The basic division of thermistor is NTC & PTC. NTC is negative temperature coefficient, the resistance offered by NTC thermistors decreases with temperature, while the resistance offered by PTC or positive temperature coefficient thermistor resistance offered increases with temperature.

Resistance Temperature Curve of NTC & PTC Thermistors

Parameters Considered For Thermistor Construction

Temperature Range: First thing to consider while selecting temperature sensor will be temperature range. Thermistors have a wide temperature range varying between -50°C to 250°C which enables them to be used in wide range of applications.

Accuracy: Among the basic type of sensors, the highest accuracy is withing the range of 50°C to 100°C and up to 250 °C for glass encapsulated thermistors. The accuracy range varies between 0.05°C to 1.00°C.

Stability: Thermistor stability may change over time depending on the material, construction, packaging etc. An epoxy coated thermistor may change by 0.2°C/year while hermetically sealed one changes only 0.02°C/year.

Packaging: The packaging is dependent on the product and environment in which the thermistor is used. They can be epoxy coated or glass encapsulated.

Noise immunity: They should be able to offer excellent immunity towards electrical noise and lead resistance.

Electrical properties: NTC thermistors must have specific current-time, voltage-current & resistance-temperature characteristics.

Comparison Between Axial & Radial Glass Encapsulated NTC Thermistor

| Parameter | Axial | Radial |

|---|---|---|

| Operating Temperature | -45°C to 250°C | -55°C to 300°C |

| Bill | Fernandez | |

| Dissipation Factor | ≥2.0 mW/C in still air | ≥2.0 mW/C in still air |

| Dave | Hill | |

| Thermal Time Constant | ≤12 seconds in still air | ≤6.5 seconds in still air |

| Tolerance | High tolerance on resistance & β value | Tight tolerance on resistance & β value |

| Resistance | 25C 2k ohm, 5k ohm, 10k ohm, 20k ohm, 47k ohm, 50k ohm, 100k ohm, 200k ohm, 500k ohm, 1.388-million-ohm etc | 2k ohm, 10k ohm, 49k ohm, 50k ohm, 100k ohm, 200k ohm,231.5k ohm |

Applications Of NTC Thermistors

There are a wide range of applications in which NTC thermistors are used.

Home Appliances: Various home appliances that use temperature concept like irons, cloth dryers, fridge, freezers etc use thermistors to monitor the temperature and regulate the same.

Medical Devices: Used in various devices used for measuring temperature like thermometers, glucose monitoring patches etc.

Electrical Vehicles: Used to ensure safety in electrical and hybrid vehicles like monitoring the temperature of battery.

Computing Devices: Used to prevent over heating of the devices in server power supply products and data line products.

Us-Electronics provides wide range of

NTC & PTC thermistors that is compatible to the industry standards which ensures that the devices are safe and sound from un expected temperature changes or surges.